Petr Vasina

Masaryk University, Czech Republic

Title: Ductile behavior of hard MoBC and WBC nano laminated coatings

Biography

Biography: Petr Vasina

Abstract

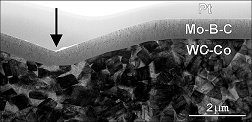

State-of-art ceramic materials nowadays used as protective coatings such as TiN, TiAlN, c-BN, etc., generally exhibit high hardness and high stiffness. These positive features are often accompanied by negative brittle deformation behavior. To overcome this limitation, a new generation of materials with high hardness and moderate ductility is desired. Recently, there has been an increased interest in boron and carbon based nanolaminates such as Mo2BC. According to the ab-initio models, these materials were predicted to exhibit unusual combination of high stiffness and moderate ductility. The coatings were deposited either by DCMS at extremely high substrate temperature of 900°C or at moderate temperature of 380°C employing HiPIMS. In our research, co-sputtering of Mo (W), C and B4C targets to finely tune the coating composition of Mo2BC and W2BC was used. Mid-frequency pulsed DC plasma excitation was employed to enhance the ion flux on the substrate by factor of three compared to DCMS case which promoted the crystallization of Mo2BC. Coatings with the same XRD patterns as those deposited by HiPIMS at the same substrate temperature were prepared. The moderate deposition conditions resulted in growth of partially crystalline Mo2BC coatings with nano composite structure where small Mo2BC crystallites of approx. 10 nm sizes were embedded in an amorphous matrix. These coatings showed high hardness of 31.6±0.8 GPa and extremely high fracture toughness– it was even impossible to form a crack in these coatings at extremely high indentation load with cube corner indenter where both the coatings and the underlying hard-metal substrate were severely plastically deformed. Only a shear/slip plane defects typical for ductile materials were detected. This required ductile behavior of hard coating observed for partially crystallite Mo2BC with nano composite structure.

Recent Publications

1. L. Zabransky et al, 2016, Thermal stability of hard nanocomposite Mo-B-C coatings, Vacuum, In Press

2. L. Zabransky et al, 2016, Nanostructured Mo-B-C Coatings, Rom. Rep. in Phys., 68(3), 1069

3. L. Zabransky et al, 2016, On the study of the mechanical properties of Mo-B-C coatings, EPJ-AP, 75(2), 2471

4. Zemlicka et al, 2016, Principles and practice of an automatic process control for the deposition of hard nc-TiC/a-C:H coatings by hybrid PVD-PECVD under industrial conditions, Surf. Coat. Technol., 304, 9

5. Soucek P, 2014, On the control of deposition process for enhanced mechanical properties of nc-TiC/a-C:H coatings with DC magnetron sputtering at low or high ion flux, Surf. Coat. Technol. 255,8