Ahmad Kadhim Jassim Al-Dawod

University of Basrah, Iraq

Title: Prediction of hardness, yield strength, and tensile strength for single roll melt spinning of 5083 Al-alloy ribbons

Biography

Biography: Ahmad Kadhim Jassim Al-Dawod

Abstract

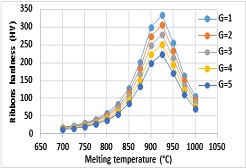

In this paper, an empirical model is applied to predict the hardness, yield strength and tensile strength of rapid solidified ribbons. The discovered empirical equation is obtained depends upon the experimental results of rapid solidification process for 5083 Al-alloys. The empirical equations predict values and describe the behavior of ribbon with consideration of ribbon thickness, grain size, hardness, yield strength and tensile strength. The experimental work involves different operation conditions and the results indicate that orifice diameter, nozzle roll wheel gap and melting temperature have direct impact on the quality of alloy. Additionally, the results showed that there is a good agreement between experimental and predicted values where the correlation coefficient is 0.99. The experiment show that there is a possibility to produce very thin ribbons with thickness in micrometer by reducing the distance between nozzle and roll wheel, and reduce the orifice diameter of casting. The hardness and yield strength will be increased due to increasing the number of small grain size in the ribbons structure and rapidly heat transfer of the small ribbons thickness. Moreover, the optimal melting temperature of this alloy is 925ºC which produces high ribbon hardness compared with other melting temperature that used in this research.

Recent Publications

- A. A. Bogno. A. Mairte, H. Henein, and Ch. A. Gandin (2014) Characterization of rapidly solidified metallic alloys using combination of experiments and modeling. COM 2014 Conference metallurgists' proceedings.

- Ahmad K. Jassim, Ali S. Hammood (2014) Single roll melt spinning technique applied to produce micro thickness rapid solidified ribbons type 5083 Al-Mg alloy. International parallel conference on researches in industrial and applied science.

- Ahmad K. Jassim, Ali S. Hammood (2014) Sustainable manufacturing process for bulk metallic glasses production using rapid solidification with melt spinning technique. International conference on material science and material engineering.

- Ahmad K. Jassim, Ali S. Hammood (2014) Single roll melt spinning technique applied as a sustainable forming process to produce very thin ribbon 5052 and 5083 Al-Mg alloy directly from liquid state. Elsevier, Science direct, pp. 133-137.

- B. Karpe et al., (2011) Modeling of heat transfers in the cooling wheel in the melt-spinning process. Journal of achievements in materials and manufacturing engineering. Volume 46, issue 1, International OCSO world press, PP. 88-94.