Mark Schvartzman

Ben-Gurion University of the Negev, Israel

Title: Soft thermal nanoimprint lithography

Biography

Biography: Mark Schvartzman

Abstract

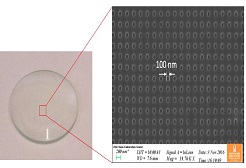

Nanoimprint lithography (NIL) can be performed using two types of resists. In the UV nanoimprint, a liquid UV curable resist film is embossed at the room temperature, and hardened by UV-crosslinking. Such resists can be imprinted either by rigid or soft (elastomeric molds). In thermal nanoimprint, a film of thermoplastic resist is embossed when heated above its glass transition temperature. This type of nanoimprint is not compatible with soft molds, whose relief features would deform while pressed against the highly viscous molten polymer. This limitation precludes many application of thermal NIL, such as ultra-high resolution nanopatterning of curved surfaces. In this work, we introduce a novel concept of hybrid Soft-Substrate-Rigid-Feature (SSRF) nano imprint mold, which is based on soft substrate with rigid relief features. The SSRF mold was fabricated by electron-beam lithography of Hydrogen Silsesquioxane (HSQ) on a sacrificial substrate, followed by transferring the obtained HSQ features to elastomeric PDMS substrate. Anti-adhesive coating, which is usually used for hard Si based molds, was successfully applied on SSRF mold, and was shown to be essential for robust demolding after the imprint. SSRF molds were used to imprint thin films of Polymethyl Benzacrylate – a thermal resist with the glass transition temperature around 60 oC. This is, for the best of our knowledge, the first time that a thermal NIL was done with soft elastomeric molds. Furthermore, to demonstrate the uniqueness of our approach, we thermally imprinted PBMA films applied on lenses. In summary, we demonstrate here a novel concept of facile and robust mold for thermal nanoimprint lithography, which will pave a way to the broad variety of applications impossible up today.

Recent Publications

- L. Menahem and M. Schvartzman “Soft nanoimprint mold with rigid relief features for improved pattern transfer”, J. Vac. Sci. Technol. B 35, 010602 (2017)

- L. Goren-Ruck, D. Tsivion, M. Schvartzman, R. Popovitz-Biro, and E. Joselevich, “Guided growth of Horizontal GaN Nanowires on Quartz and their Transfer to Other Substrates” ACS Nano, 8 (3), 2838 (2014)

- M. Schvartzman, D. Tsivion, D. Mahalu, O. Raslin, and E. Joselevich, “Self-Integration of Nanowires into Circuits by Guided Growth” Proc. Nat. Acad. Sci. USA, 100 (38), 15195 (2013) (

- D. Tsivion, M. Schvartzman, R. Popovitz-Biro, and E. Joselevich, “Guided Growth of Horizontal ZnO Nanowires with Controlled Orientations on Flat and Faceted Sapphire Surfaces” ACS Nano, 6 (7), 6433 (2012]

- D. Tsivion, M. Schvartzman, R. Popovitz-Biro, P. von Huth, and E. Joselevich, “Guided Growth of Millimeter-Long Horizontal Nanowires with Controlled Orientations” Science, 333 (6045), 1003 (2011)