Robert Beckenlechner

University of Stuttgart, Germany

Title: Graphite based minimum quantity dry lubrication at drilling CFRP

Biography

Biography: Robert Beckenlechner

Abstract

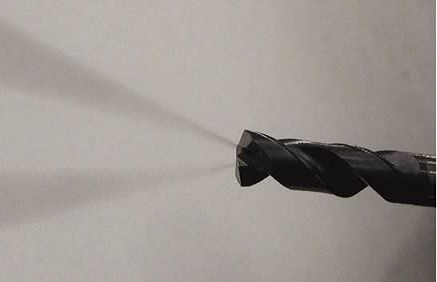

The machining of carbon fiber reinforced plastic (CFRP) causes high tool wear and thus induced costs. One approach is to use liquid cooling lubricants e.g., Minimum Quantity Lubrication (MQL), as known from metal cutting. Due to the unlimited types of CFRP and cooling lubricants, chemical interactions between them cannot be excluded. The humidity of cooling lubricants can also affect the mechanical properties of the CRFP, like a softening of the matrix. An additional consequene can be a reduced fiber-matrixadhesion which results in lower fracture toughness. Therefore, this article presents a new MQL technology, which is completely dry. For this purpose, a prototypical fluidization device was constructed. It boosts minimal amounts of graphite powder by using compressed air to the cutting zone between the tool and work piece. Graphite was selected as dry lubricant because of three reasons: First, graphite can be used as a dry lubricant; second, the contamination by graphite powder is not relevant as the dust and chips from the cutting process are extracted by exhaustion anywhere and; third, chemical interactions between the carbon fibers and graphite are not to be expected. By spraying tests with internally cooled drills, it was shown that the current fluidization device is already able to deliver graphite mass flows less than 3 g/h reliably. First drilling tests with internal MQDL-supply have shown a significant reduction in tool wear, compared with cooling by pure compressed air. Finally, a H2O-enrichment device was constructed to extend the fluidization prototype. The aim is to include foreign molecules in the lattice structure of the graphite by using H2O-molecules. As described in literature, the sliding characteristics of graphite are improved by these additional molecules. The H2O-enrichment device is able to achieve almost a 90% relative humidity of the compressed air that is used to transport the graphite.

Recent Publications

Mitschang, P. (2014): Fertigteilbearbeitung. In: AVK – Industrievereinigung Verstärkte Kunststoffe e. V. (Hg.): Handbuch Faserverbundkunststoffe. Grundlagen, Verarbeitung, Anwendungen; mit 46 Tabellen. Wiesbaden: Springer Vieweg, S. 509–521.

Walter, A. et. al. (2012): Spanende Bearbeitung von Leichtbauwerkstoffen: Einführung und Überblick. Hg. v. e-mobil BW GmbH - Landesagentur für Elektromobilität und Brennstoffzellentechnologie Baden-Württemberg, FraunhoferInstitut für Produktionstechnik und Automatisierung (IPA), Ministerium für Finanzen und Wirtschaft Baden-Württemberg und Ministerium für Wissenschaft, Forschung und Kunst BadenWürttemberg. Stuttgart.

Hänle, P. (2010): Hochleistungswerkzeuge für die Bohrungsbearbeitung mit MMS: Entwicklungen zur Steigerung der Prozesssicherheit. In: Braun, S.; Maier, W. und Zirkelbach, S. (Hg.): Intelligent produzieren. Liber amicorum. Berlin, Heidelberg: Springer-Verlag Berlin Heidelberg, S. 143–147.

Suresh Kumar Reddy, N.; Venkateswara Rao, P. (2006): Experimental investigation to study the effect of solid lubricants on cutting forces and surface quality in end milling. International Journal of Machine Tools & Manufacture 46 (2006) 189–198

Nageswara Rao, D.; Vamsi Krishna, P. (2008): The influence of solid lubricant particle size on machining parameters in turning. In: International Journal of Machine Tools and Manufacture 48 (1), S. 107–111. DOI: 10.1016/j.ijmachtools.2007.07.007.