Haider M. Mohammad Albu-Swelim

University of Basrah, Iraq

Title: Optimization of sustainable cutting conditions in turning carbon steel by CNC turning machine

Biography

Biography: Haider M. Mohammad Albu-Swelim

Abstract

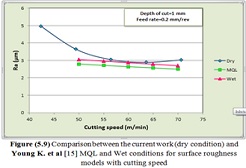

The current study aims to find the optimum cutting parameters in turning process without using cutting fluids (dry cutting condition) towards sustainable manufacturing, where the power consumption and environmental pollution increases due to increase of the machining operations in manufacturing field. So, in order to save energy and environment and reduce cost, it is important to adopt sustainability in machining processes. The experimental work in this study involves the preparation of experiments on AISI 1045 carbon steel to collect the necessary data for implementing optimization process. The experiments were conducted by changing levels of cutting parameters (spindle speed, feed rate and cutting depth) in CNC turning machine. Surface roughness of the work piece has been depended as a quality indicator. Also the temperature of cutting tool has been recorded during machining the work pieces in order to control the temperature of cutting process. Theoretically, empirical equations for temperature of cutting tool and surface roughness of the work piece have been discovered. By using genetic algorithm technique, these equations have been used to find the optimum of cutting parameters spindle speed, feed rate and depth of cut. The optimum values obtained by genetic algorithm achieved sustainable cutting; spindle speed 588.96 rpm, depth of cut 0.50 mm and feed rate 64.55 mm/min in order to have the optimum of surface roughness in low cutting temperature.

Recent Publications

- Elena G, Giacomo F (2014) What Is Sustainability? A Review of the Concept and Its Applications: Springer International Publishing Switzerland.

- Janez K, Franci P (2009) Concepts Of Sustainable Machining Processes: 13th International Research/Expert Conference, Trends in the Development of Machinery and Associated Technology, Hammamet, Tunisia, 16-21 October.

- K.F,Man et al (1996) Genetic Algorithm: Concepts and Applications: IEEE Transactions on Industrial Electronics, Vol.43, No. 5, October.

- M. Cemal Cakir, et al (2009) Mathematical Modeling of Surface Roughness for Evaluating the Effects of Cutting Parameters and Coating Material: journal of materials processing technology, Vol. 209.

- Singiresu S. Rao (2009) Engineering Optimization, Fourth Edition, John Wiley & Sons, Inc,.

- Young K, Choon M (2010) Surface Roughness and Cutting Force Prediction in MQL and Wet Turning Process of AISI 1045 Using Design of Experiments: Journal of Mechanical Science and Technology, Vol. 24.